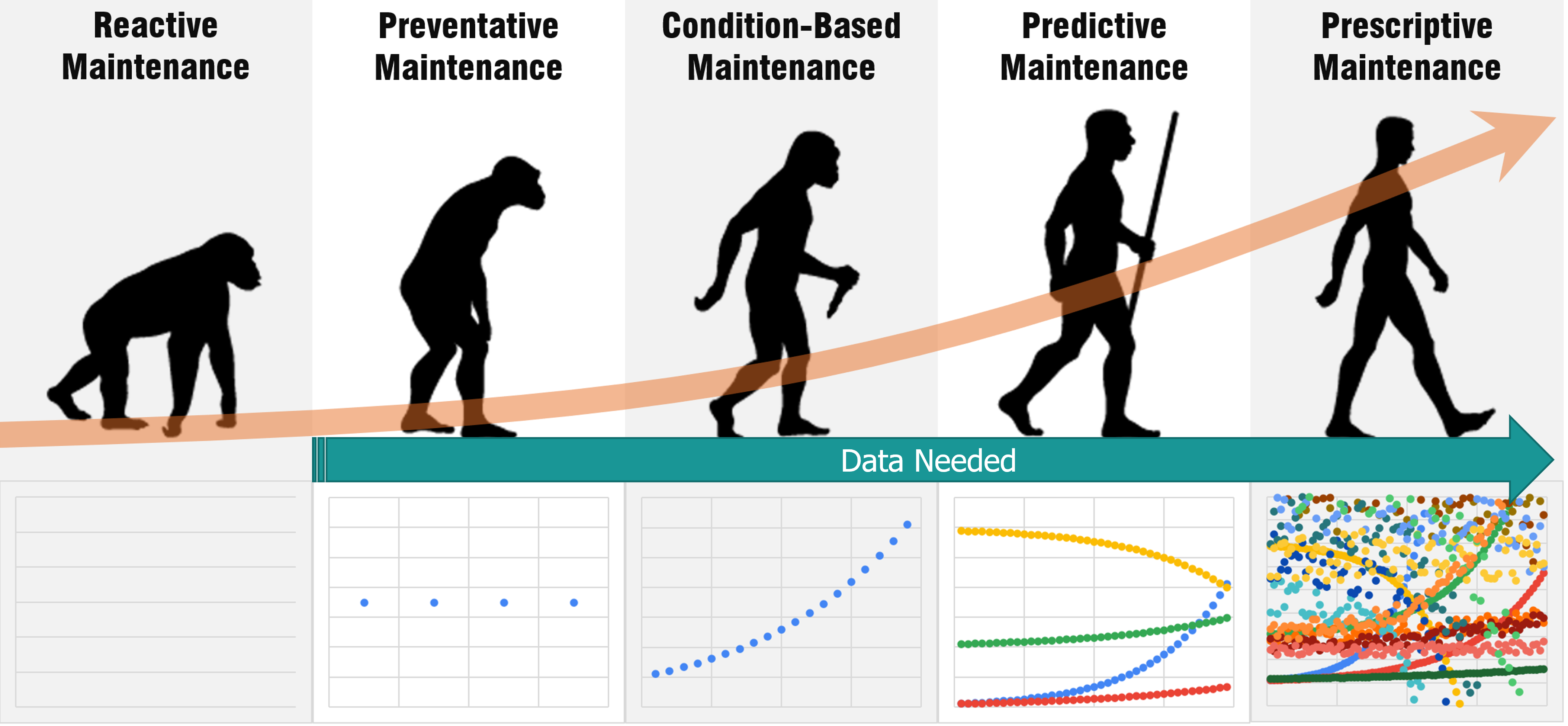

The evolution of maintenance

Which maintenance strategy are you using?

- Reactive maintenance has absolutely no dependence on data, it waits for failure. 35% of failure modes are run to failure.

- Preventative maintenance uses either time or usage to inform its maintenance schedule, it's not a lot of data - but it's a start. 5% of failure modes require preventive tasks

- Condition-based maintenance will typically look at a few metrics and check against pre-set thresholds.

- Predictive maintenance typically looks at a handful of data sets and relies on slightly better analytics to pick up on various trends in the data and the health of the asset.

- Prescriptive maintenance uses many data sets and metrics embedded into ML (Machine Learning) & AI (Artificial Intelligence) to predict failures before they occur.

Our ultimate goal is to prescribe maintenance and prevent failures, plan downtime and maximize uptime.

-

Become more proactive and save time

Want to increase uptime and efficiency? With our digital solutions, you can see both scheduled and upcoming maintenance needs, for any individual lift truck or a whole fleet. You can also see an estimate of time for labor and what spare parts will be required for each checkpoint, optimizing the usage of time and resources efficiently.

-

Preventive maintenance made easy

Having a Smart Connected Lift Truck makes your maintenance planning easy. A smart connection gives you full insight into the overall maintenance status of the vehicle. If used together with CheckApp for daily inspections, this can be an even more powerful tool to increase uptime in a reliable way that saves you both time and money.

For you who want to:

Reduce costs

Increase productivity

Increase safety